| Types of inflatable shafts |

| Hits:1461 AddTime:2023/6/14 17:47:52 |

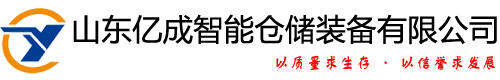

| Types, structures, and manufacturing of inflatable shafts: The use of square core shafts for retracting and unwinding in equipment such as axial paper rolling machines, slitting machines, and printing machines has been widely used to this day. But it is only suitable for low speed, low winding quality, high loading and unloading labor intensity, and unsafe. On this basis, two types of mechanical expansion shafts have been developed, one is the paper release shaft of the parting machine, and the other is the core shaft of the longitudinal cutting and rewinding machine. The structure is relatively reasonable and the manufacturing is more accurate, but it is difficult and labor-intensive. In recent years, there have been more and more inflatable shafts with new structures used in retractable devices both domestically and internationally. We have been exploring and trial producing them, and have received praise from users. Now we will introduce the structure of the inflatable shaft, so that more mechanical factories and users can improve their understanding and understanding of it, making it easier to manufacture, update, and promote. 1. Types of inflatable shafts: From a structural perspective, the inflatable shaft can be divided into three categories so far: the first type is a common type used for winding and unwinding, as shown in Figure 1, Figure 2, and Figure 3. The second type is used in high demand winding, as shown in Figure 4 and Figure 5. The third type is used in special requirements, as shown in Figure 6. 2 1.1 protruding button type (cylindrical head is a slider) inflatable shaft (Figure 1), blade type (double round head flat key is a slider) inflatable shaft (Figure 2) In Figure 1 and Figure 2 of the first type, the rollers are usually made of seamless steel pipes. One type of roller surface is drilled with circular holes, and the other type is milled with double round head long holes. The inner body of the roller is equipped with an air tire. The outer surface of the air tire is divided into several sections by 4-6 metal strips (milled from unlinked steel pipes). Both ends of the air tire are sealed with sealing sleeves and gaskets. The end is sealed by tightening the nut, and one end is equipped with a gas pipe and nozzle. The protruding button type cylindrical head or blade type flat key are fixed on the metal strip. The protruding button type, the metal strip is connected by copper welding after drilling a circular hole, while the blade type flat key slider, the metal strip is milled into a long groove, and the flat key slider is pushed forward from the groove using a spring plate to determine its position. This ensures that the flat key precision block can expand and move freely in the roller body hole. Then, the metal strip is connected by copper welding, in order to ensure a longer service life of the pneumatic tire and the lowest position of the block shrinkage, Install a cylindrical lightweight rod (aluminum tube, hard plastic tube, wood) into the pneumatic tire, especially when the diameter of the tire is large and the length is long. When the tire is stopped, the middle part of the rubber tube can prevent the inner wall from sticking, causing premature folding and cracking.

In order to increase the aesthetics and service life of the inflatable shaft, the slider is plated with hard chromium with a thickness of 0.03-0.05mm, and the outer surface of the roller is plated with decorative chromium with a thickness of 0.02-0.04mm. The connection between the roller body and the shaft head is made with screws for easy assembly and disassembly. Usually, the air nozzle is located in the operating side shaft head (sometimes for convenience, both the transmission eight roller surface and the operating side roller surface ends are equipped with air nozzles). There is a keyway in the transmission eight shaft head, which can be used for transmission or braking. The diameter of the roller body is 74mm (i.e. 3), with a length of 600mm and 800mm. 2200mm, 2400mm, can withstand construction as needed φ 100, φ The length of l50mm and the shape and size of the shaft head are designed and manufactured according to the requirements. 2.1.2 Four or six curved surfaces (in contact with the inner wall of the paper garlic tube) The circular arc shaped metal plate inflatable sleeve (Figure 3) is a pneumatic core tube fixture with a narrow door width, which has been used for 40 years to replace the mechanical tightening head. It can be used individually or in combination on a square or sun axis. As shown in the figure, the individual structure is a short core shaft, with a drilled vent hole and an air nozzle in the center. The middle part is covered with a rubber tire, and the two ends of the cabin are tightly tied to the middle part of the shaft to prevent air leakage. The outer side of the rubber tire is a set of movable curved plates, usually 4-6 pieces, made of aluminum sheet metal. Milled fine lines on the surface in the length direction to increase friction with the inner wall of the contact paper core tube. Countersunk screw holes are drilled at both ends and connected to the shaft core with hexagonal screws, leaving a certain amount of movement (radial) margin. Once ventilated, the rubber tire expands, pushing up the movable curved plate to firmly support the outer core tube. The connection method for the shaft end can be flange, pulley, or other methods.

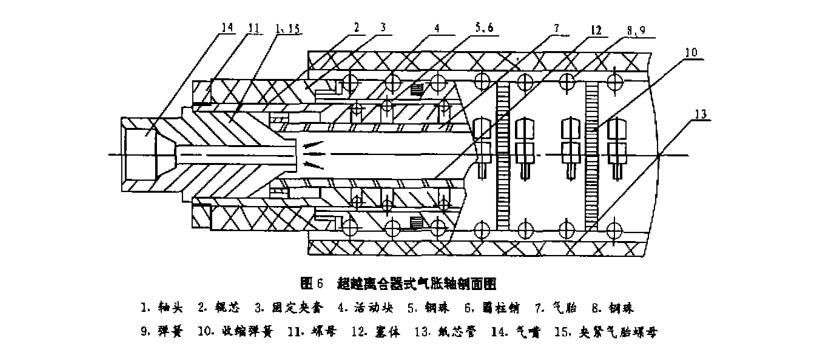

2.2 The second is the long and healthy trachea type inflation shaft (Figure 4) For large diameter inflatable shafts, the manufacturing method is to use a roller body made of a thick walled seamless steel pipe. On the roller surface, according to the diameter and usage requirements, longitudinally mill (plane) and cut into 6-8 irregular grooves (symmetrically distributed), and lay special rubber tube pneumatic tires in the grooves. The outer side of the pneumatic tire is equipped with a plastic metal long key, and each group (symmetrically distributed) of pneumatic tires has a first connection to the roller core air pipe. The roller body and the long key are divided into several sections to install springs, with an inflation pressure of 0.6MPa. The shaft heads at both ends are connected to the roller body with bolts. There is an air nozzle installed at the end of one shaft. Once ventilated, each tire inflates, and the long body evenly expands. On the contrary, the spring in the groove of the roller surface acts on each long body to contract. The outer surface of the roller is plated with decorative chromium, with a thickness of 0.02-0.4mm. The Changjian is plated with hard chromium, with a thickness of 0.03-0.05mm. Roll body diameter φ 255m m φ 374mm,... length 3400mm, 4400mm. For manufacturing methods with smaller diameters, there are two options. For roller body materials with larger sizes, 45 and 40C r are used, and for Changjian, 20 steel is used. The roller body is made of solid round steel and milled with I-shaped long grooves, and equipped with long keys. Special aluminum alloy extrusion molding and polishing are used for batch manufacturing, roller bodies, and long keys. And it is processed by individual parts, and the outer surface of the roller and the long key must undergo hardening treatment. It is wear-resistant and beautiful. It has been successfully trial-produced by Zhejiang Ningbo Controller Co., Ltd. and is highly welcomed by users. The application of different plastic long grooves can be as follows: 3.4.5.6.8 ··· 1. For rubber hoses, their outer diameter is usually φ 10mm, φ 12mm, φ 14m m. φ 16mm,... The wall thickness is 2.5-4mm. Requirements for driving pipes: (1) Have expansibility, elasticity, and fatigue resistance, such as φ After 10mm inflation, choke and inflate to φ 18mm does not crack or leak, and can restore its original shape and size after venting. (2) The floating particles of the filler should be fine, evenly distributed, free of impurities, and free from sand holes and pores. (3) The surface of the pipe wall must be smooth and free from orange peel. (4) It can withstand air pressure of 0.6M Pa, with an average inflation and deflation time of 15-20 minutes every 24 hours. The service life should be more than one year. For air nozzles, due to the increasingly widespread use of inflatable sleeves and varying inflation and deflation frequencies, users require the inflator gun to be able to inflate immediately without forcing it tightly, saving labor and time. Therefore, various requirements are put forward for the structure of the air nozzle, but they are not afraid to directly use motorcycle air nozzles. Due to different shapes and lengths, the design structure is required to be compact, reasonable, labor-saving, firm, and have a long service life. Commonly used gas nozzles, due to the metal surface of the valve core plane and the gas nozzle of the inflation gun, the surface is required to be smooth, and the operator needs to use a lot of force when inflating. To prevent air leakage. Improved nozzle structure. There is a seal at the end of the air nozzle that matches the inflation gun mouth, and the valve core is connected by a conical surface. For the connection method between the rubber head and the distributor, a head joint is usually used, with one end threaded into the distributor and the other end threaded into the inner hole of the rubber head. The rubber head is padded with fabric and tied tightly with lead wire. The hose does not leak air. It is relatively simple, but during the process of inflating and deflating the rubber head, the time is slightly longer, and the rubber hose at the joint ruptures and leaks air. The reason is that this type of rubber hose has a soft texture and a cloth clip (not allowed). It has been demonstrated from practice. This connection method is not advisable. The construction adopts new and other connection methods to ensure long service life and convenient disassembly and assembly of rubber hose joints. 2.3 The third is. Overrunning clutch type inflatable shaft (as shown in Figure 6) The roller body is a seamless steel pipe, and a handful of small holes are drilled on the roller surface. There is a lining strip on the inner wall, and column pins are embedded on it, aligned with small holes. There is a steel ball at the head of each column pin (which will not fall outside the small hole of the roller body). There is an air tire in the roller core. Fixed on the two end shaft head, with one end for air intake. There are forty irregular long slider bars on the outer surface. The shape consists of a circular shape, with a slanted hole drilled on the outer edge and spring steel balls installed. Its cross-sectional view resembles a surpassing platform release device. There are ten sleeves at both ends of the long slider for positioning, and a locking nut is screwed onto the roller body at the outer end of the sleeve to effectively control the position of the long slider. The outer circle of the long slider is segmented into grooves, and spiral springs are installed in the grooves. When the pneumatic tire is inflated. The column pin steel ball supports the long slider, and the steel ball on the slider compresses the spring. The long slider compresses the inner wall of the paper core tube, and the paper core tube is integrated with the roller body. On the contrary, when the air is released, the spring in each slot on the long slider contracts, and the steel ball on the slider is ejected by the spring, causing the long slider to detach from the inner wall of the paper core tube. The long slider of this structure bears uniform force on the contact surface between the inner wall of the paper core tube, and the deformation of the paper core tube (or thin plastic sleeve) is small, ensuring its original roundness. Therefore, it is better for the fourth degree of the rolled workpiece. But manufacturing is complex. The cost is also high, and it is suitable for cigarette paper, cable paper, adhesive tape paper, etc. which are rolled into a narrow sheet for grazing after being cut into pills. Conclusion: The inflatable shaft plays a very important role in both the paper industry and other industries, ensuring the quality of the retractable parts and reducing the loss rate.

|

| 【Refresh】【Favorites】【Print】 【Close】 |

| Previous:50KN.m CNAS certificate Next:Yangzhou Flying Spur 250Kw Motor Test Bench |

Products

- Torque speed sensor

- torque speed sensor

- Magnetic powder clutch

- Magnetic powder brake

- Tension control system

- Deviation control system

- Safety chuck

- Air shaft

- Eddy current brake

- Hysteresis brake

- Hysteresis clutch

- Hysteresis dynamometer

- Eddy current dynamometer

- Magnetic powder dynamometer

- Electric dynamometer

- Hydraulic dynamometer

- Chassis dynamometer

- Motor test bench

- Engine, axle, gearbox, PTO test bench

- Reducer test bench

- RV, Harmonic and Planetary Test Bench

- Actuator, worm gear box, test bench

- Traction machine test bench

- Drill pipe test bench

- Hydraulic wrench test bench

- Slewing bearing test bench

- Hydraulic pneumatic motor test bench

- Non-standard custom test bench

- Acquisition instrument

- Testing software

- New Energy automobile gearbox test bed

- High and low temperature test box

- Coupling

- Industrial Water Chillers

Contact us

Jiangsu Lanmec Technology Co., Ltd.

Tel:0513-88801222

0513-88801555

0513-88802555

Fax:0513-88802999

Add:222 Long'an North Road, Hai'an, Nantong, Jiangsu,China